We support you. Produce your plastic products efficiently.

Tederic 'NEO series' injection molding machines.

Reliable and economically attractive.

Efficient.

Would you like to strengthen your market position?

We focus on the best solution for you.

Reliable.

Do you pay attention to a stable value chain?

Increase your productivity with our production solution.

Electric.

Do you produce valuable products for your customers?

Our injection molding machines are powerful.

Active.

Would you like to optimize your production and avoid downtime?

We live 'Customer Care' and deal with your issues.

Economical production solutions.

For plastics processors.

The duration of product life cycles is declining. Accordingly, the demand for cost-effective production solutions to produce a valuable end product on a stable running machine and with an application-specific process is increasing.

Advantages of the Tederic 'NEO series' for your applications:

High flexibility and high functionality

High process stability and high reliability

High usability and simple operator guidance

High efficiency and high availability

Your personal contact listens carefully in order to understand your requirements. In line with our experts, he defines a reliable and efficient production solution for you. He will provide you with tailor-made advice to ensure your economic success.

Our production solutions offer numerous advantages:

High-performance injection molding machine from 4 series (drive system electric, all-electric and hydraulic)

Professional machine control, type KEBA in standard (screen sizes 12 or 15 inch)

Convenient standard equipment for a wide range of applications and compliance with existing standards (including CE conformity; Euromap)

Application-specific support, project planning and service

Tederic Machinery Ltd. was founded in Hangzhou in 2003. Since that time, the company has become one of the top three Chinese injection molding machine manufacturers. The 'NEO series' with its four lines was developed with an international team of experts and was launched worldwide in 2021. The four series can be used to manufacture valuable products, including those in the automotive, packaging, medical, logistics, and construction industries, as well as for household appliances and consumer goods. The Tederic Linear Robot TLR makes injection molding automation economically attractive and easy.

Tederic ‚NEO series‘.

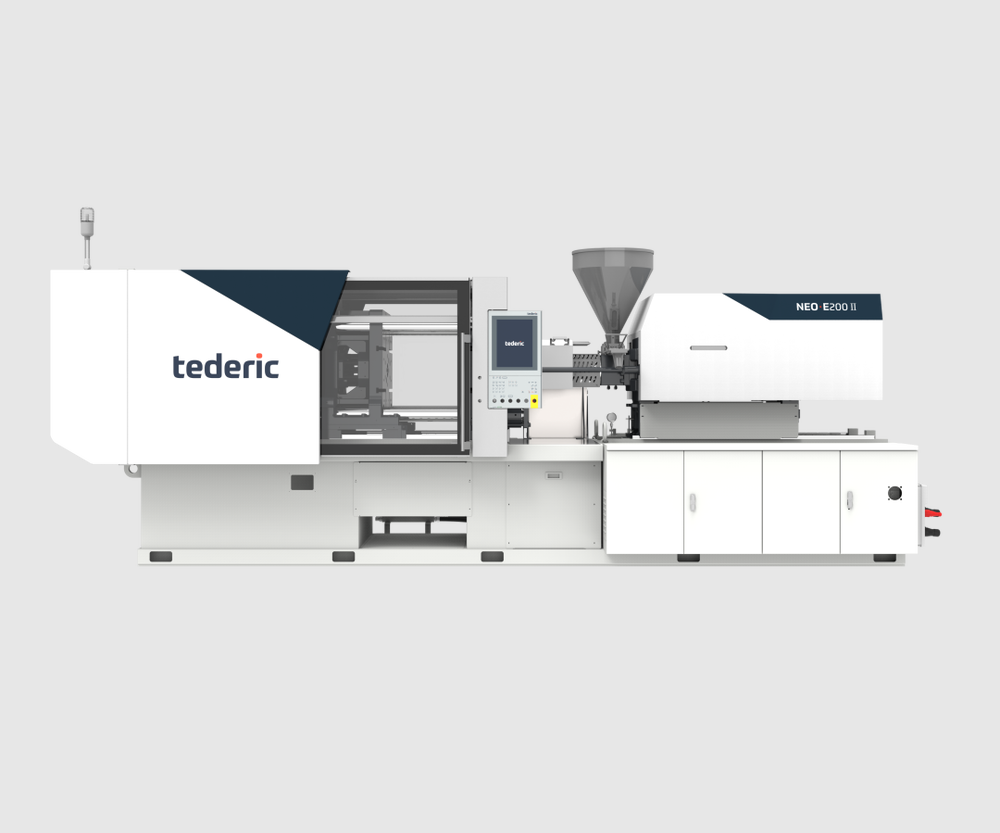

NEO·E: Powerful electric

toggle injection molding machine

NEO·E

Clamping force

60 t - 1.400 t

Screw diameter

20 mm - 120 mm

Shot weight

6 g - 6.104 g

Clamping force NEO∙H:

Clamping force sizes of the 2nd generation

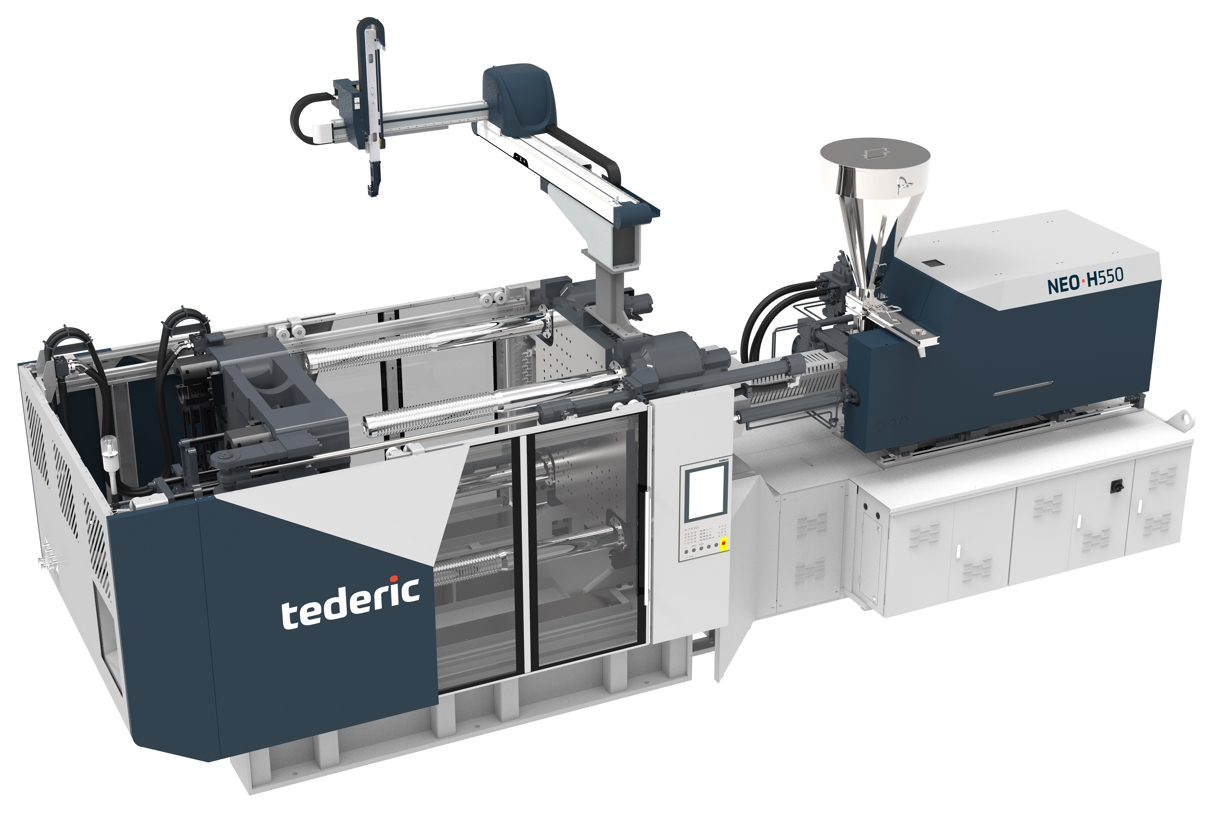

NEO·H: Modern hydromechanical

two platen injection molding machine

NEO·H

Clamping force

550 t - 5.500 t

Screw diameter

75 mm - 260 mm

Shot weight

331 g - 61.794 g

Clamping force NEO∙H:

Clamping force sizes of the 2nd generation

NEO·M: Multi-component injection molding machines

based on the NEO·H

NEO·Ms

Clamping force

880 t - 3.520 t

Screw diameter

45 mm - 120 mm

Shot weight

72 g - 7.087 g

NEO·Mv

Clamping force

1.120 t - 1.920 t

Screw diameter

50 mm - 120 mm

Shot weight

98 g - 9.968 g

NEO·T: Cost-efficient hydraulic

toggle injection molding machine

NEO·T

Clamping force

90 t - 1.050 t

Screw diameter

35 mm - 120 mm

Shot weight (HP)

35 g - 2.582 g

Linear robot TLR: Injection molding automation

economically attractive and made easy

TLR

Loading capacity

3 kg - 50 kg

Conveyor belts

Up to 6 m lenght und 1,2 m width

Safety enclosures

CE compliant

Why PlastiVation?

We are there for you. Personally.

We are a strong team of experts with a combined experience of over 350 years in the plastics industry. With Tederic, we have gained a partner who, with its 'NEO series', offers the right performance features for numerous injection molding applications as well as trends such as the circular economy, industry 4.0 and digitalization.

We are personally there for you. Strengthen your market position as an owner-managed and medium-sized plastics processor. Keep your value chain stable. Produce valuable end products for your customers. Optimize your production and avoid downtime.

Your investment. Your bonus.

The profitability of your investment is our top priority. However, we do not only provide you with competent support on the selection of state-of-the-art and high-performance injection molding machines.

Starting with the project planning of your injection molding cell, we already have your complete production environment in mind and take its requirements into account.

With our 360° approach, we go beyond the mere selection of an injection molding machine. According to your needs, our focus is also on automation, the right peripherals, the digital ecosystem, and intralogistics as well as the exact integration into your production.

Our project management ensures the smooth introduction and integration of your new injection molding system into your production environment.

Our services in the areas of project planning and project management for your sustainable production advantage:

Project planning and project management

Customized machine equipment

Automation solutions (robots)

Peripherals and accessories (e.g. temperature control units, material supply)

Planning of the injection molding system according to your requirements

Smooth integration of the injection molding systems into your production

Your contact person for Germany, Austria and Switzerland.

Qualified and committed.

Thomas Strecker

30 years plastics industry

What drives me: "Actively providing the most economical production solution for customers supported by a solid service package."

Marco Schönekäß

21 years in the plastics industry.

What drives me: "To create the best solution for my customers so that they advance in their markets".

Andreas Bexte

36years in the plastics industry

What drives me: "Delivering clients the most efficient production solutions for sustained success, while actively collaborating to sculpt their future using state-of-the-art technology."

Get in touch!

Our mindset? Driving our customers.

Appreciative.

You are not a number with us.

We talk to you personally.

Apposite.

We don't beat around the bush. We actively tackle and handle your issues.

Reliable.

Communication is on equal footing.

We listen and create the best solution for you.

To your benefit.

You do not pay for a glass palace.

We are digitalizing.

Our experts look forward to hearing from you.

Please feel free to use the contact form for this purpose, call us to make an appointment

or email us your requirements.

PlastiVation Machinery GmbH

Tel: +49 89 200 65 89 0

Email: sales@plastivation.com

Copyright© 2021 Plastivation: Maschinenbau für Kunststoffverarbeiter